FVE Mystěves

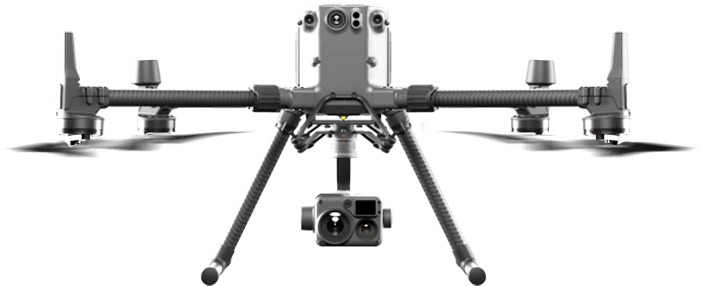

Spolupráce s firmou DroneTech byla bezproblémová. Zákazník před vlastním provedením termovizní zkoušky dodá elektronicky podklady, které slouží k naplánování trasy létajícího stroje. Po dohodě termínu, vlastní realizace proběhla ve velmi krátkém čase. Samotné vyhodnocení snímků k velikosti elektrárny taktéž vyhovovalo. Rozlišení termovizních snímků je dostatečné a dají se na nich bez problému najít jednotlivé vadné články.

Shrnutí:

Termovizní zkouška za pomoci dronu je velmi časově nenáročná. Pomocí této metody lze objevit nepřeberné množství typů závad na fotovoltaických panelech. Nevýhoda u této metody měření je, že není možné prověřit jednotlivé konektory či vnitřní vybavení rozvaděčů. Myslím si však, že i s tímto nedostatkem si pánové bez problémů dokáží poradit.

Firma: Apros Group, s.r.o.

Instalovaný výkon:

1,5 MWp

Roční ztráta výkonu:

39 427 kWh

Roční finanční ztráta:

551 986 Kč